YTSF Inducted Fan

Product Introduction

1. The Third Party Testing Report

The aerodynamic performance test report (issued by national inspection institution, Hefei General Machinery&Electrical Products inspection Institute).

2. PRINCIPLE AND APPLICATION

The theory of the pushing inducted fan is derived from the characteristics of high-speed jet flow in aerodynamics. The high-speed jet flow with high kinetic energy is used to disturb the surrounding air and bring the air to a specific target direction. The central velocity of the jet flow gradually decreases from the exit point of the nozzle while the width of the jet flow increases and the induced surrounding air also gradually increases. The increased surrounding air on the one hand dilutes the indoor harmful gas, and drives the indoor air flow on the other hand which makes the harmful gas concentrate and quickly move to the exhaust fan along the preset air passage. The harmful gas is discharged outdoors through the exhaust fan so that create a good indoor exchange air effect.

The inducted fan can effectively reduce the concentration of harmful gas in large indoor places, maintain good air and improve the indoor environment.

Application in: Metro vehicle depot, underground parks and supermarkets, warehouses.industrial workshops, stadiums, other large places and large-area induced ventilation required places.

3. PERFORMANCE FEATURES

a. High efficiency and energy saving, high air exchange quality, small size, easy installation, free maintenance and easy to clean;

b. With purifier at inlet (from a professional company) and functions of filtration, dust collection, purification and disinfection, easy cleaning and maintenance; (Optional)

c. With adjustable double louver at fan outlet and the air outlet angles of upper, lower, left and right directions can be adjustable;(optional)

d. CFD simulation analysis: CFD flow field simulation analysis and optimization can be carried out according to customer requirements and specific site conditions;

e. Low noise: the muffler layer of the whole fan can effectively reduce the noise;

f. Optional materials: customers can choose galvanized plate (plastic-sprayed surface) or stainless steel pate as casing material according to their needs;

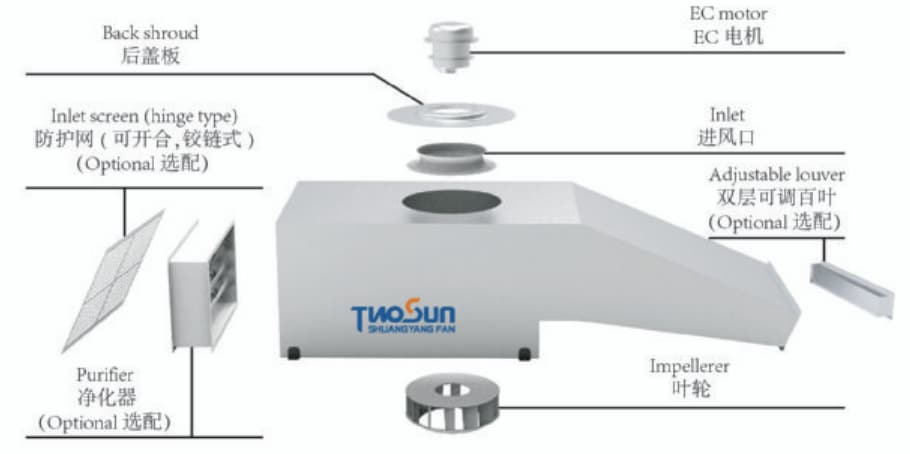

4. Fan Structure

The centrifugal fan, with backward curved impeller, is driven by EC brushless external rotor, direct driven. The overall shape of the fan is flat and lone. The motor is installed inside the fan to reduce the fan height and installation space. And the special inclined fan outlet makes the jet air flow cover the operating area of the man-machine workstation well.

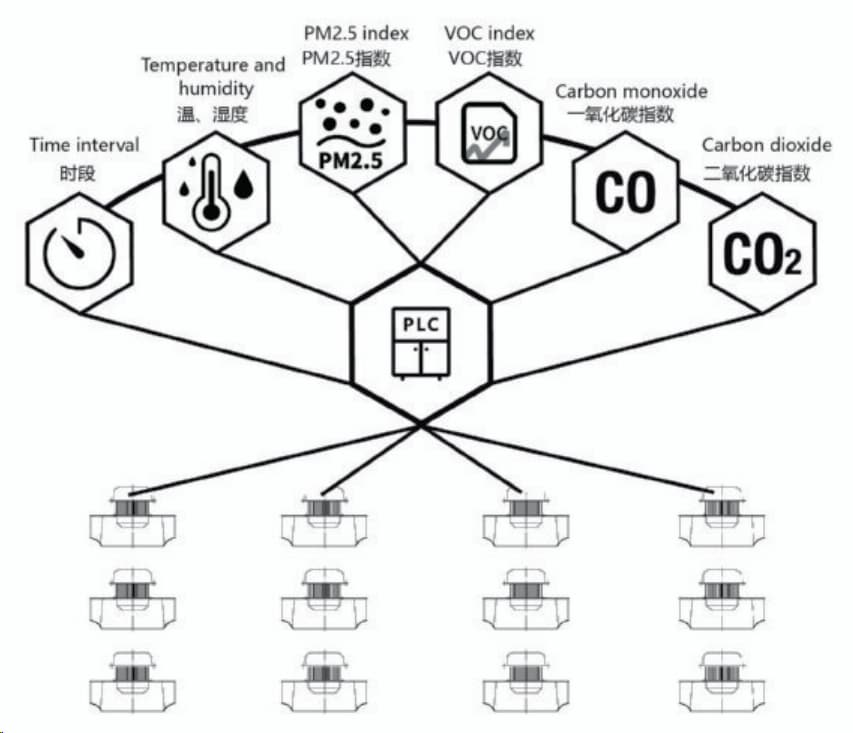

5、Control plan

The control cabinet can be connected with the application in mobile phone and the function of communication with BAS is reserved.

Data Display Function:

a. Real-time data display;

b. Equipment running status display;

c. Process monitoring display;

d. The historical curve shows;

Control function:

Control modes: local control and central control

a. Local control function:

Manual start/stop fan according to the requirements of the track at site, and the fan speed can be automatically adjusted according to the ambient temperature collected by the temperature sensor after fan start. Shift operation mode can be set according to non-operating hours and off-peak operating hours. Operating modes can be set according to season (spring and autumn, summer and winter), temperature, VOC,time setting, manual control, etc. Real time display of energy consumption of a single fan and fan number.

b. Central control:

Total energy consumption data in year, month and day can be displayed on the central control end, which is convenient for operation and maintenance management reference. Centralized computer control by industrial serial communication (RS485) can reduce energy consumption and fan noise and prolongs the life of the fan. According to the industrial serial communication protocol, fan revolution, fan power and other real time information of fan will be uploaded to the BAS. The status of equipment overload and overheating, fan alarm and other information can be

displayed, at the same time, this information is uploaded to BAS through the industrial serial communication protocol.

Note: indexes of temperature, humidity, carbon monoxide, carbon dioxide, PM2.5 and VOC can be added as monitored items as required. And according to the actual needs of the project site, the required functions can be customized.