Shot Blasting in Fan Manufacturing

Shot blasting is a mechanical surface treatment process used in the production of fans (e.g., metro tunnel fans, ventilation fans, fire smoke exhaust fans) to achieve several critical functions:

Surface Cleaning: It removes impurities such as rust, mill scale, oxide layers, and contaminants from metal surfaces, ensuring a clean substrate for subsequent coatings or treatments.

Surface Activation: The process creates a uniform, slightly roughened texture on the metal, which improves adhesion for paints, coatings, or anti-corrosion layers, enhancing long-term durability.

Stress Relief: By bombarding the surface with high-speed metallic abrasives (e.g., steel shots), shot blasting induces compressive residual stresses. This strengthens the material, reduces fatigue cracks, and improves resistance to wear and deformation under operational stresses.

Deburring: It smooths sharp edges or burrs left from machining or welding, ensuring safer handling and smoother airflow dynamics in fan components.

Corrosion Resistance: By eliminating weak surface layers and enabling effective coating adhesion, shot blasting significantly extends the lifespan of fans exposed to harsh environments, such as humidity, chemicals, or high temperatures.

Overall, shot blasting enhances structural integrity, reliability, and performance of fan products, making it essential for applications demanding high safety and durability standards.

Top 10 Ventilating & Fire Smoke Exhaust Fan Manufacturer From China

Top 10 Ventilating & Fire Smoke Exhaust Fan Manufacturer From China

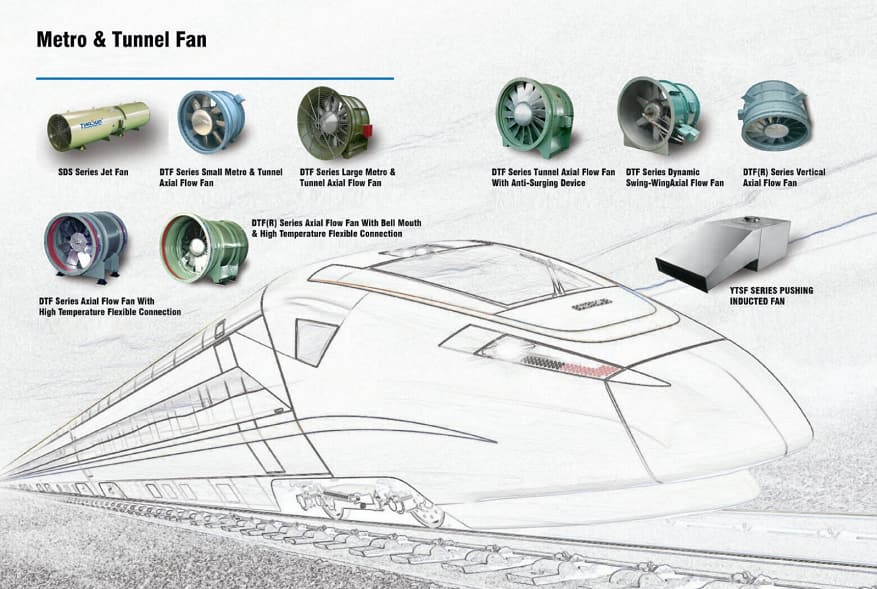

The 4th Production Base for Metro Tunnel Fan

The 4th Production Base for Metro Tunnel Fan

School Enterprise Cooperation

School Enterprise Cooperation

Shot Blasting in Fan Manufacturing

Shot Blasting in Fan Manufacturing