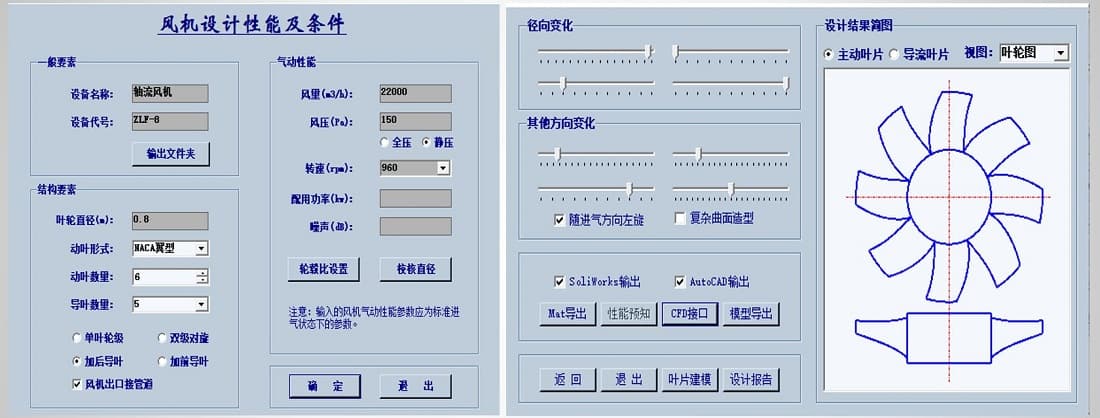

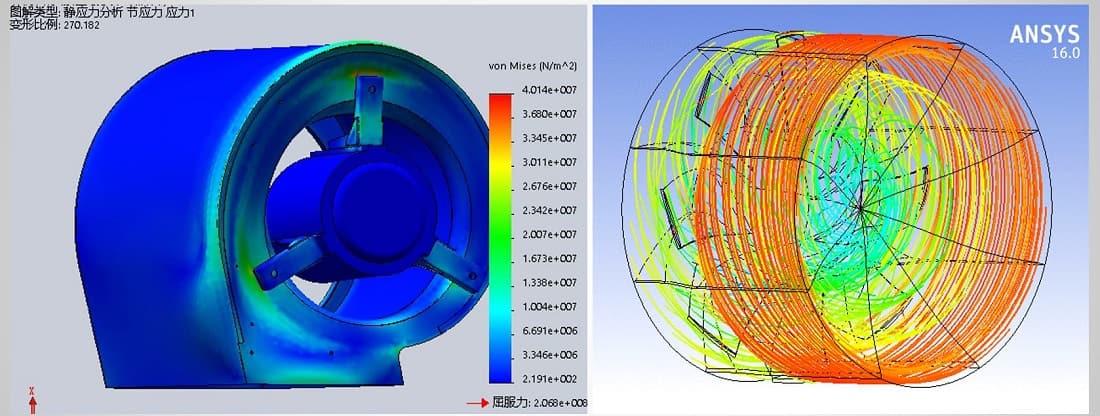

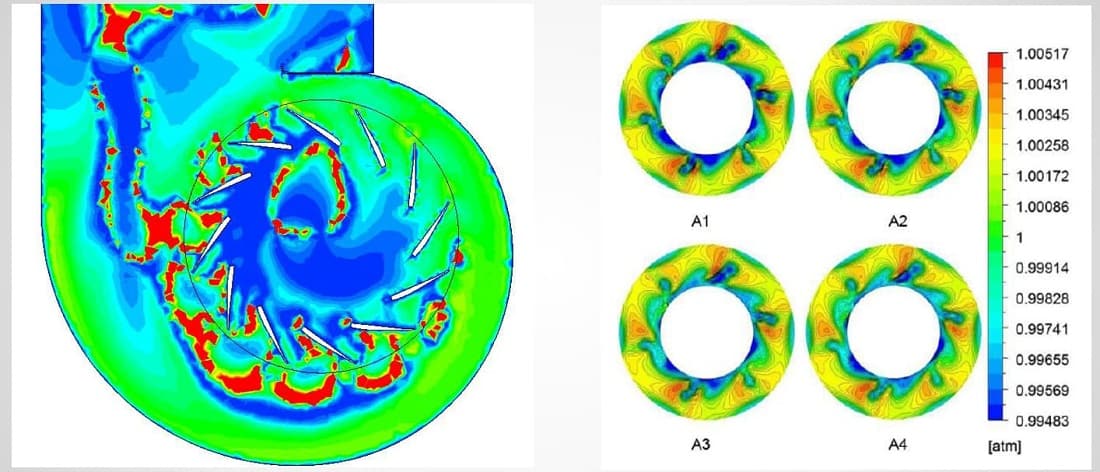

Scientific Design, Selection and Production Process

Shuangyang Fan utilizes computer-aided technology and advanced testing and inspection methods to develop a scientific design and production process, significantly improving product development efficiency while ensuring the safety and reliability of fans.

Top 10 Ventilating & Fire Smoke Exhaust Fan Manufacturer From China

Top 10 Ventilating & Fire Smoke Exhaust Fan Manufacturer From China

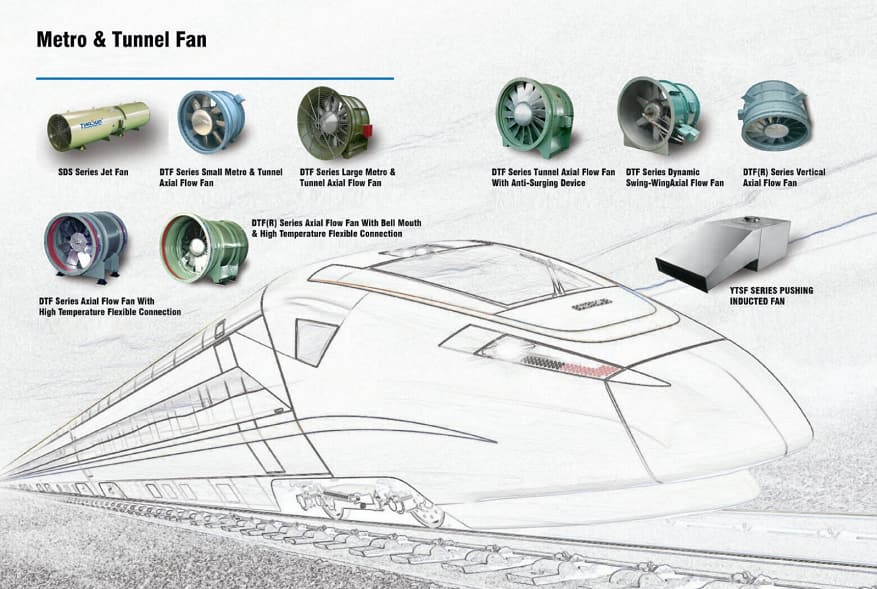

The 4th Production Base for Metro Tunnel Fan

The 4th Production Base for Metro Tunnel Fan

School Enterprise Cooperation

School Enterprise Cooperation

Shot Blasting in Fan Manufacturing

Shot Blasting in Fan Manufacturing